When every unit matters

Quality has always been at the core of JMC Engine. It is evident in every process and decision, from production method development to manufacturing and customer service. Also, quality and environmental certificates have been the foundation for over 20 years, and we continuously strive to improve our operations.

Driving Quality at JMC Engine

As a contract manufacturer JMC Engine produces and delivers items exactly according to customers’ needs. Therefore, quality requirements and standards come directly from customers, further emphasizing the importance of quality control. Every component must work seamlessly together to achieve a high-quality result.

One of the key figures in driving JMC Engine’s quality is Quality and Development Manager, Tapio Jouhten, who leads the quality team. Quality team’s responsibilities cover a wide range of quality control and development work. Tapio’s career path at JMC Engine is an inspiring example of how individual growth and development can go hand in hand with the company’s growth.

After high school Tapio began his studies at the University of Applied Sciences in 2005, graduating as an engineer in mechanical and production engineering in 2009. “My first contact with JMC Engine was the summer jobs in 2006 and 2007. Four years later, I inquired about available job positions and got a three-month contract, which continues today,” Tapio laughs. Starting in assembly work and moving to the machine shop, Tapio has been advancing JMC Engine’s quality control with his quality team of for over ten years.

Quality plays a role in RFQ-stage

Tapio emphasizes that quality assurance accompanies every stage of the production process, and the quality team has a pivotal role already in the RFQ-stage. “Together with our sales and engineering team, we review the customer’s requirements and instructions to ensure quality and plan a suitable solution for the customer.”

Setting up the production process with quality in focus

Quality team and engineering work together seamlessly when designing the production for new items. Quality control is systematically developed throughout the production process, even before the prototype is made, taking into account potential manufacturing risks. Design Review is a meeting with the customer, involving the raw material supplier and JMC Engine. “This level of collaboration ensures that all parties agree on the product’s quality requirements and manufacturing processes. It is the core of the process, where all manufacturing parties bring their expertise to the design,” Tapio says.

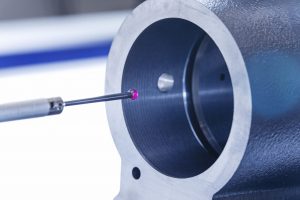

Once the prototype is manufactured, it is thoroughly examined, “We use various measurement methods and research techniques to ensure that the product meets all the customer’s requirements before starting serial production,” Tapio explains.

Systematic quality control

Quality planning at JMC Engine is a process of continuous improvement, using statistical process control and other development tools. We focus on measuring all critical features as dimensions and surface qualities of the product to ensure that the product matches the customer’s drawings and other requirements.

In serial production, quality assurance systematically verifies the production process’ quality capability and compliance. It is done through regular and random measurements, ensuring continuous quality monitoring and maintenance throughout all stages of product development.

Actions to Ensure Quality Commitments

Although JMC Engine aims to produce flawless quality, complaints may still occur. Every complaint is carefully handled and analysed, and corrective action is taken immediately. Additionally, we ensure that the measures have been effective to prevent similar problems from occurring in the future.

JMC Engine’s commitment to quality is comprehensive and covers the entire personnel, not only the quality team. “We have a continuous ambition to improve our processes and quality capability. Our quality team wants to lead the way and we communicate effectively with all stakeholders, ensuring that quality always remains our top priority,” Tapio says.

Leave a Reply

Want to join the discussion?Feel free to contribute!