JMC Engine Cooperates Closely With Foundries

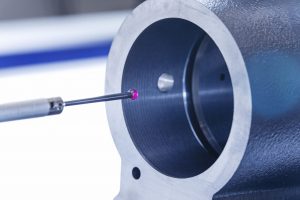

JMC Engine is one of the leading contract manufacturers in precision machining and component production in Europe. Our specialties are cast iron components that require accuracy and extremely high level of quality, such as cylinder heads, valve guide mechanisms and fuel injection systems. Our core competences are efficient and streamlined serial production processes where the castings are made into components that fulfil all the customer requirements. To uphold these processes and the quality of the end product, the requirement for the raw casting and the performance of the foundry are equally high.

JMC Engine Oy works closely with the foundries. It is a part of our strategy, where we cooperate to ensure the high quality of the end product. This collaboration is pivotal so that we can offer our end customers an easy and effortless way to source machined castings from a one-stop-shop. We recognize this need together with foundries and strive to offer the best possible solution. Our partnership with Eisengiesserei Baumgarte is an excellent example of this.

Eisengiesserei Baumgarte as an Excellent Foundry Partner

Most of the modern foundries in Europe can meet the stringent demands of the end customers today. Our partner, Eisengiesserei Baumgarte is one of Germany’s premier foundries that show continuous commitment to quality and development. Established in 1932, Baumgarte serves several industries including pump technology, mechanical engineering, construction, vehicle construction and railway systems. Their annual capacity is 30,000 tonnes and they utilize advanced casting techniques to produce complex and precise castings.

Eisengiesserei Baumgarte’s Sales Manager Frank Grimm has worked with JMC for almost 15 years. “Four years ago, I changed the company and had the pleasure to continue the successful co-operation with JMC Engine in my new job. We have found a competent (development) partner for the machining and assembly of highly complex cast components. With JMC and the joint sales work, we have also succeeded in acquiring new markets and customers.”

Eisengiesserei Baumgarte focuses on comprehensive customer orientation at all levels. Consultancy, development, value analysis, and design are the basis and origin of technically and economically perfectly designed cast parts with the clear objective of realising and further developing all customer requirements in the best possible way.

“We consistently measure the success of innovations by our ability to design and initiate them. The satisfaction of our customers is always our daily challenge”, Grimm says, “In JMC, we have found a partner who works according to the same philosophy. Therefore, the cooperation with JMC is outstanding in all areas: from design and development to production/scheduling and quality assurance. True to the motto: nothing is impossible.”

Combining Strengths Ensures the Optimal Outcome

Our close cooperation with Baumgarte ensures that every stage in production of a precision machined casting is in the hands of the best professionals in the field. The quality of the casting is a central factor for the end product to fulfil all the requirements. Best results are reached when the casting process and the machining process are observed and developed together. This way, for example, the effects of a casting change can be considered in the potential needs to change the machining process.

It is very important that the foundry and the machinist approach the quality and development in a similar fashion. And both have competent resources for planning and development. Then the end customer can enjoy the results and avoid the complex development work altogether. Together with our partner our mutual goal is to provide the end customer with the best possible offering.

A Partnership Built on Mutual Respect and Open Communication

At the core of our relationship with Baumgarte is a commitment to open, honest communication. This transparency fosters trust and facilitates a collaborative environment where both parties are encouraged to bring their ideas and challenges to the table. It is through this partnership that we can innovate and adapt to market changes more effectively, ensuring that we continue to offer our clients the best possible solutions.

“JMC is a partner that has not only an extensive, modern, and efficient machine park but also an extensive service package to go along with it (mechanical processing, finishing, testing, assembly). Thanks to the expertise of the people involved, we have successfully managed to be involved in the development process of new components for our customers as early as possible and to help design them. We appreciate the open and fruitful discussions and the proactive communication”, Grimm says.

Future Aspirations

“We are convinced, that we are on the right track with JMC and that our joint work will lead to sustainable success,” Grimm specifies and continues, “We would like to thank the entire JMC team for their outstanding support and cooperation up until now and ‘Team Baumgarte’ is looking forward to a long-term partnership.”

As we continue to find new customers, a strong partnership will play a pivotal role. We are proud to partner with Eisengiesserei Baumgarte. Our combined strengths will propel us forward, enabling us to unlock new potentials and continue leading innovation and customer satisfaction.