Vastuullista, luotettavaa ja laadukasta sopimusvalmistusta

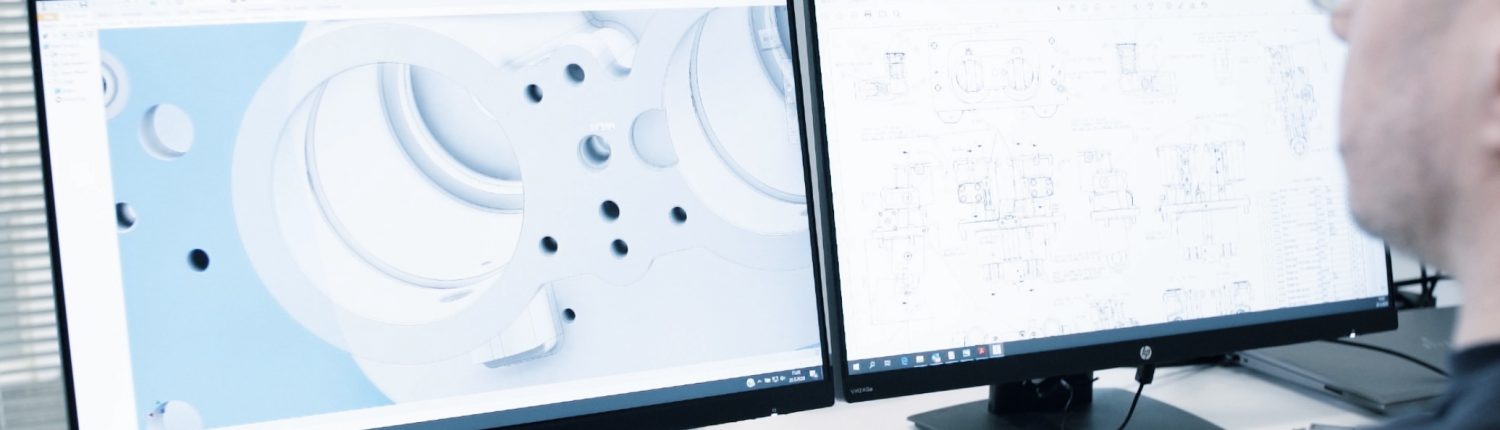

JMC Engine on yksi Euroopan johtava tarkkuuskoneistusta ja komponenttivalmistusta tarjoava sopimusvalmistaja. Erikoisalueemme on erityistä tarkkuutta ja laatutasoa vaativat valurautakomponentit, kuten suurten moottoreiden sylinterikannet, venttiilien ohjausmekanismit ja ruiskutusjärjestelmät.

Olemme erikoistuneet työskentelemään asiakkaan kanssa läheisessä yhteistyössä. Jokainen tuote ja spesifikaatio, työkalu ja mitta, henkilö ja yhteydenotto on meille tärkeä.

Maailman johtavat moottorivalmistajat luottavat tapaamme toimia.

Varmista tuotteesi laatu ja saatavuus – valitse JMC Engine.